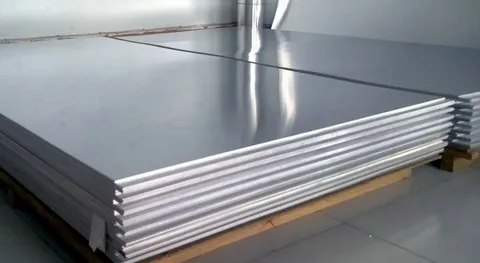

Aluminium plates are widely used in construction, manufacturing, transportation, and even DIY projects due to their strength, lightweight nature, and resistance to corrosion. However, with a wide variety of grades, sizes, and finishes available, how to choose the right aluminium plate for your project can be a challenging task. This guide will help you navigate the key considerations when selecting the best aluminium plate for your needs.

Understanding Aluminium Grades

The first step in determining how to choose the right aluminium plate for your project is understanding the different grades available. Each grade has specific properties suited for particular applications:

- Grade 1100: Known for excellent corrosion resistance and workability. Ideal for chemical equipment and food processing.

- Grade 5052: Offers great strength and corrosion resistance. Commonly used in marine and automotive applications.

- Grade 6061: One of the most versatile and widely used alloys. Suitable for structural applications, aerospace, and machinery.

- Grade 7075: Extremely strong and used in aerospace and military applications, but less corrosion resistant.

Knowing the mechanical and physical properties of each grade helps in selecting the right one based on your project’s demands.

Consider the Plate Thickness

Another important factor when deciding how to choose the right aluminium plate for your project is the thickness of the material. Thicker plates are generally used in heavy-duty applications such as aerospace and construction, while thinner plates are suitable for signage, enclosures, or lightweight structures.

- Thin plates (0.5mm to 3mm): Ideal for lightweight fabrication.

- Medium plates (3mm to 6mm): Used in structural and general-purpose applications.

- Thick plates (6mm and above): Suitable for industrial and load-bearing uses.

Choose the thickness according to the load, environment, and performance requirements of your project.

Surface Finish and Treatment

Aluminium plates are available in various finishes such as mill finish, brushed, anodized, or coated. The choice depends on both aesthetic and functional needs:

- Mill Finish: Raw, unpolished surface; economical but not very attractive.

- Brushed Finish: Offers a clean and modern look; often used for decorative purposes.

- Anodized Finish: Enhances corrosion resistance and appearance.

- Coated Plates: Provide extra protection in harsh environments.

When considering how to choose the right aluminium plate for your project, the finish can play a crucial role in determining longevity and visual appeal.

Application-Specific Requirements

Finally, think about the specific requirements of your application:

- Will the plate be exposed to the elements?

- Does it need to be welded or machined?

- Is weight a critical factor?

- What is your budget?

Matching these needs with the appropriate grade, thickness, and finish ensures that the aluminium plate performs effectively throughout the lifespan of your project.

Conclusion

Choosing the right aluminium plate might seem overwhelming at first, but by breaking it down into specific factors—grade, thickness, finish, and application—you can make an informed decision. Always keep the end use in mind and consult material specifications when in doubt. With these tips, you’ll be better equipped to answer the question: how to choose the right aluminium plate for your project—ensuring quality, durability, and success in whatever you’re building.